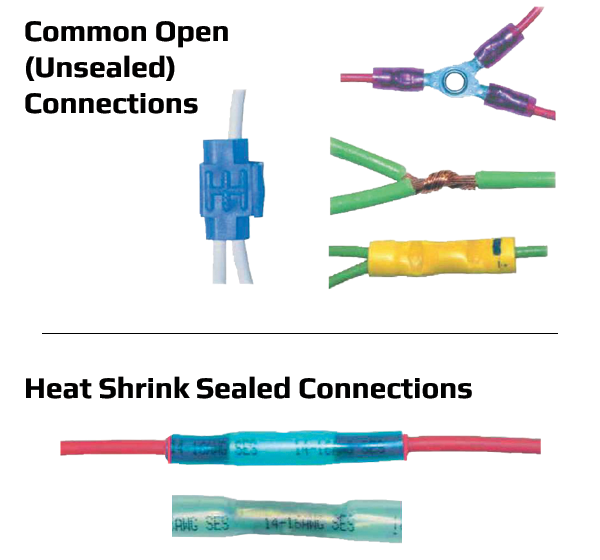

Since the majority of trailers are manufactured in the southern parts of the United States, where corrosion and weather isn’t as harsh as in Canada, a lot of trailers that are imported come outfitted with unsealed wiring connections. While unsealed wiring connections are fine in an interior setting, these types of connections cause problems when used on the exterior of a trailer as they commonly corrode with moisture.

So what’s the solution?

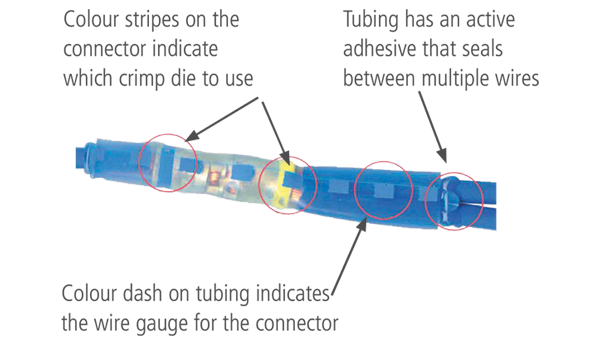

We like to use a type of connection called called a heat shrink connector. The heat shrink connector is individually protected from corrosion, contaminants, and current leakage. When heat is applied to the installed terminal, the heat shrink connector shrinks to form a protective shell over the connection, while the adhesive-sealant lining flows to fill all voids and fuse the insulation of the terminal and wire together.

We always use heat shrink connections for exterior repairs, electrical brakes, and clearance lights. While heat shrink connections are more expensive than open connections, they are more reliable and fast to install.

Multi-Wired Connectors

To replace multiple wire connections when you’re using open unsealed connectors, we have multi-wire sealed connectors. The in-line button connector enables you to put two wires in one end, and a single wire of the same gauge in the other end.

Do you have questions about the different kinds of wire connectors? Give us a call at 780-968-5433 or send us an email here and we’d be happy to answer your questions.